Poor maintenance strategies can reduce an organization’s overall productive capacity.

It can be difficult to determine how often a machine should be taken offline to be serviced as well as weigh the risks of lost production time against those of a potential breakdown.

Currently, most maintenance organizations are forced to handle this dilemma with a complicated balancing act between maximizing the useful life of a part and asset at the risk of machine downtime.

Thankfully, the rise of new connected technologies can enable machines to maximize the useful life of machine components while also avoiding machine failure.

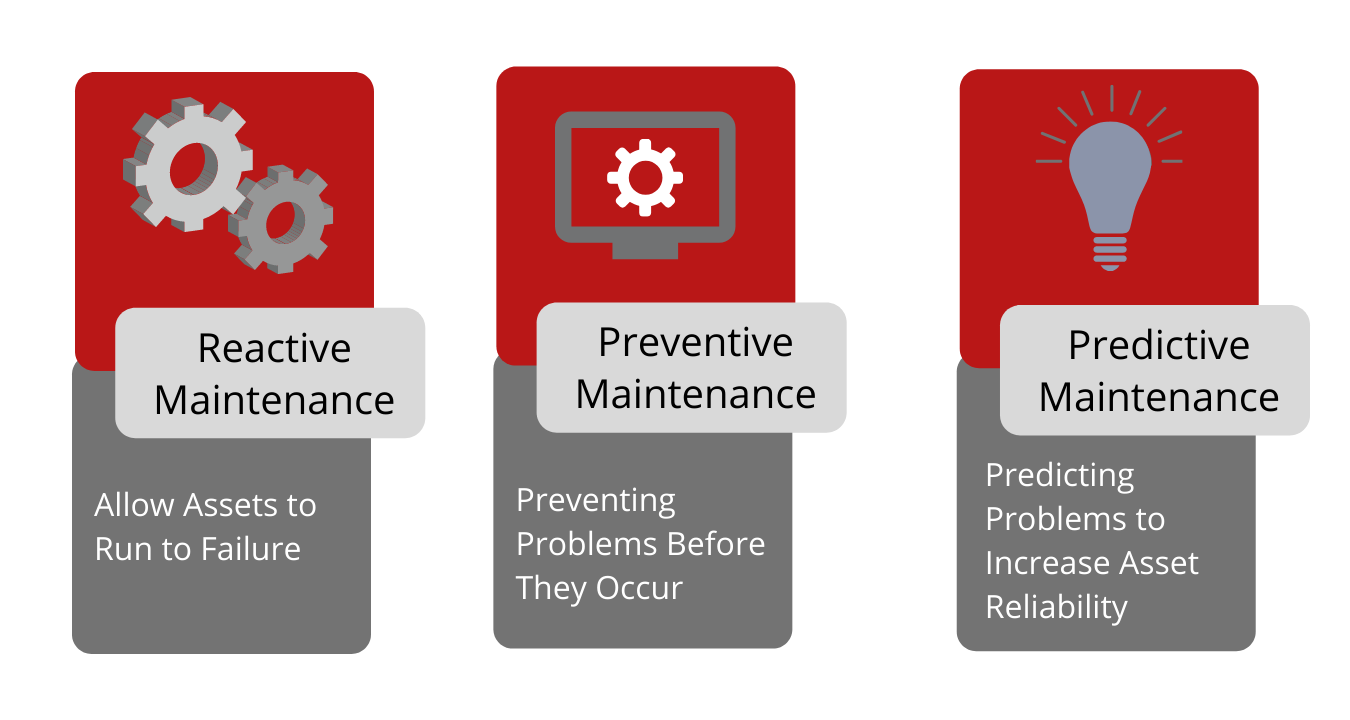

Maintenance strategies traditionally fall into one of three categories, each with its own challenges and benefits:

- Reactive Maintenance

- Preventive Maintenance

- Predictive Maintenance

1. Reactive Maintenance

What is Reactive Maintenance?

Reactive maintenance describes the strategy of repairing parts or equipment only after the asset has broken down or been run to the point of failure.

Benefits of Reactive Maintenance

Reactive maintenance is appealing because it offers the maximum utilization and in turn maximum production output, of the asset by using it to its limits.

This strategy is only beneficial, however, up until the point where the asset fails.

Disadvantages of Reactive Maintenance

The cost of repairing the asset after failure can potentially be more than the production value received by running it to failure. Furthermore, as parts begin to vibrate, overheat, and break, additional machine damage can occur, potentially resulting in further costly repairs.

When organizations utilize a reactive maintenance strategy, they often fall victim to treating the asset symptom, rather than the problem causing the symptom.

For example, your maintenance team may be repeatedly repairing an overheated bearing that could be prevented if the team was looking at the asset as a whole rather than just focusing on the one symptom.

Maintenance work, such as replacing and repairing parts and servicing equipment, can be a large financial burden to the organization.

This could be prevented by treating the problem rather than the symptoms. Learn more about reactive maintenance and common disadvantages.

2. Preventive Maintenance

What is Preventive Maintenance?

Preventive maintenance, also referred to as planned maintenance, consists of maintenance tasks performed while the equipment is under normal operation to avoid unexpected breakdowns and the associated downtime and costs.

Assets are taken offline at a specific time and preventive maintenance tasks are performed.

Benefits & Disadvantages of Preventive Maintenance

The goal of preventive maintenance is to extend the life of assets, increase productivity, improve overall efficiency, and reduce maintenance costs.

While preventive maintenance may be more cost-effective than reactive maintenance strategies, it can also be more difficult to justify.

Preventive maintenance is based on the theoretical rate of failure rather than the actual equipment performance.

This means parts are replaced while they still have a useful lifespan remaining and organizations must keep spare parts on hand.

It can be difficult to justify why preventive maintenance is the best strategy when it requires greater planned downtime, for seemingly perfect machines to be taken offline and operations to be disrupted, requiring complicated parts and inventory management. For more on switching to predictive maintenance, please see "Your Quick Guide to 5 Maintenance-as-a-Service (MaaS) Business Models of Predictive Maintenance."

3. Predictive Maintenance

What is Predictive Maintenance?

Predictive maintenance has been enabled by advances in technology that connect your assets to your data historian and/or CMMS through sensor data.

It directly monitors asset performance during normal operation to anticipate and predict failures.

Predictive maintenance analyzes the data gathered from sensors connected to assets.

Benefits of Predictive Maintenance

This data can be used to predict when an asset will fail and in turn, allows maintenance teams to correct the issue before a failure occurs.

Rather than running a part to failure or replacing it when it still has life because of protocols, predictive maintenance helps organizations optimize their strategies by conducting maintenance only when completely necessary.

Reactive vs. Preventive vs. Predictive Maintenance

| Benefits | Challenges | |

| Reactive |

Maximum utilization and production value from assets |

Unplanned downtime |

| Potential for further damage to the asset | ||

| Higher maintenance costs | ||

| Preventive | Lower maintenance costs | Need for spare parts and inventory management |

|

Less equipment malfunction and unplanned downtime |

Increased planned downtime | |

| Maintenance on seemingly perfect assets | ||

| Predictive | Connected technologies provide a holistic view of asset health | Increased upfront infrastructure management |

|

Improved analytics options |

Complex system implementation requirements including data management, technology and user adoption |

|

| Removes the need to run-to-failure or replace a part while it still has life |

Making Waves with Predictive Maintenance Analytics

The concept behind predictive maintenance is not new.

Technology, including sensors, computers, and software, has finally caught up with the concept behind the idea and more importantly, has become affordable enough for widespread implementation across an organization.

The data captured from the various connected systems and sensors make it possible for maintenance and reliability teams to analyze their assets and their maintenance strategies like never before.

Previously unavailable data allows organizations to draw conclusions about their assets and maintenance strategy that can directly impact how their maintenance teams function as a whole and how their assets are managed by predicting when malfunctions will occur.

In other words, predictive maintenance utilizes data to make smarter maintenance decisions, provide greater transparency into asset health and enable enhanced connections across systems.

The Impact of Predictive Maintenance

The goal of predictive maintenance is to solve the challenges of both reactive and preventive maintenance without running to failure or replacing a healthy part.

With predictive maintenance, planned and unplanned downtime, high maintenance costs, the potential for further asset damage, and unnecessary maintenance on working assets are decreased.

The connected technologies involved in predictive maintenance pull data from multiple systems to provide real-time insights into asset health, allowing the computers to complete the work behind the scenes and allow the maintenance managers to deploy their resources more effectively and efficiently.

With predictive maintenance and connected technologies, maintenance teams can better address the issue of the right asset with the right part and the right person at the right time.

When considering the number of man-hours spent performing routine asset inspections and preventive maintenance tasks, the justification for predictive maintenance as a strategy and optimization tool becomes obvious.

For example, let’s assume you have 50 technicians on your maintenance team and they each spend 20 hours a week performing routine inspections and preventive maintenance tasks – that’s 1000 technician hours a week dedicated to tasks that would become obsolete with a predictive maintenance strategy. Imagine what you could do with all that extra technician time.

Challenges of Predictive Maintenance

Predictive maintenance is not without its own set of challenges.

It is more complex to establish than a preventive maintenance strategy and if the proper technology is not already in place, it requires time to set up the infrastructure before specific maintenance strategies can be set in motion.

The complexity of establishing a predictive maintenance strategy includes developing areas of your business such as your equipment, technology, and user adoption protocols.

The most important business segment to establish when implementing a predictive maintenance strategy focuses on data management.

Collecting the right data to enable the organization to accurately predict failures and malfunctions is crucial.

This means, in order to implement a predictive maintenance strategy, you must first understand your asset criticality and the specific data sources required to achieve your maintenance goals.

These challenges can be easily overcome with a detailed plan of action.

Creating the foundation for predictive maintenance will help identify any barriers to success.

During implementation, your team can refer to the plan to ensure things are progressing according to it.

When a plan is put in place, companies can scale their maintenance strategies to achieve previously unattainable levels of efficiency offered through predictive maintenance.

To learn more about how Prometheus Group can help you establish and execute on a predictive maintenance plan of action, request a demo now.

FAQ: