Sometimes, all it takes is a fresh set of eyes to make you question long-held processes and habits. That was the case for one client that I was recently working with. A new manager had just started and posed a question that was challenging but fair.

“How can we effectively schedule many different crafts when we only schedule to the parent Work Order?”

The new manager raised a valid point. Even though the Scheduling team had been doing it this way for years, it was time to revisit their processes and see if scheduling to the task WOs could be more effective for them.

It’s not uncommon for some organizations to schedule to the parent WO only, but there are many advantages of scheduling to the child or task WOs.

Let’s break it down.

The Difficulties of Only Scheduling to the Parent Work Order in Your CMMS

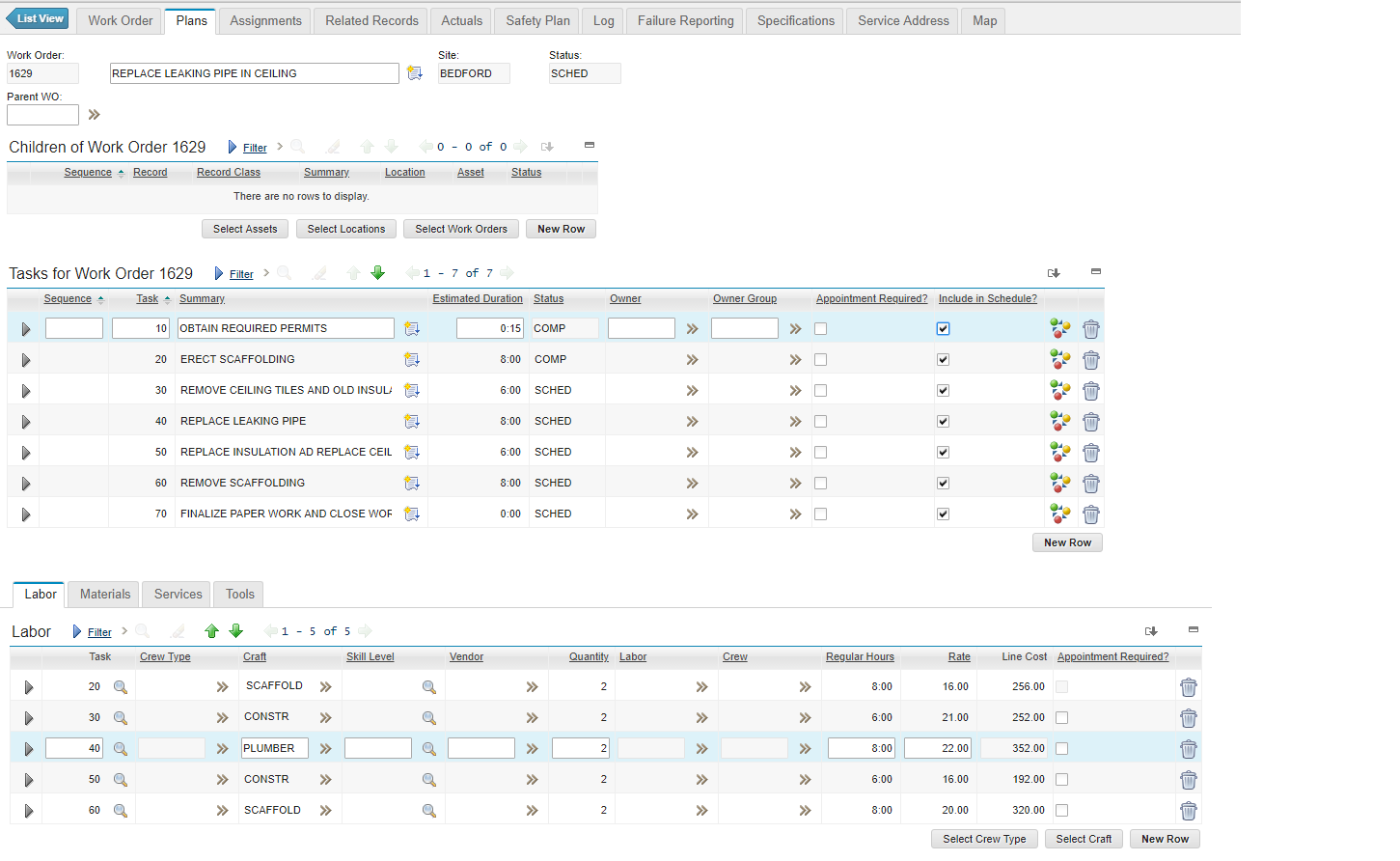

Let’s say you are scheduling a pipe replacement. It’s not simply a matter of removing the old pipe and installing the new pipe. The old pipes are in the ceiling. Before the plumbers can replace the pipes, the Planners need to get the right permits, and then other workers need to erect scaffolding and the maintenance crew will need to remove the ceiling tiles and insulation. Then, the plumbers can remove the old pipes and install the new ones. Then the insulation needs to be replaced, the ceiling tiles put back, and the scaffolding deconstructed. Lastly, any paperwork would need to be finalized.

All in all, that’s actually seven tasks and at least two or three different crafts for what on the surface sounds like one job.

How can you tell when one task is done before the others when all Assignments are at the parent WO level?

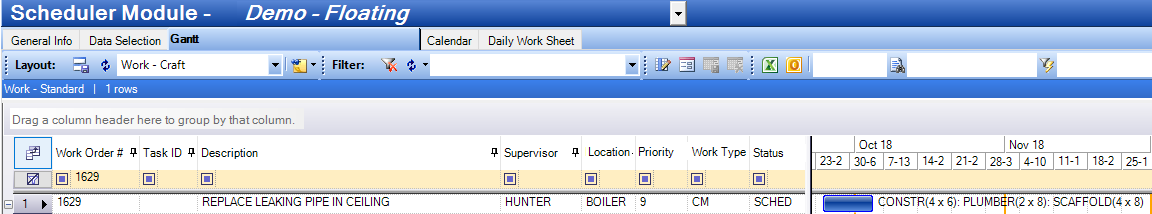

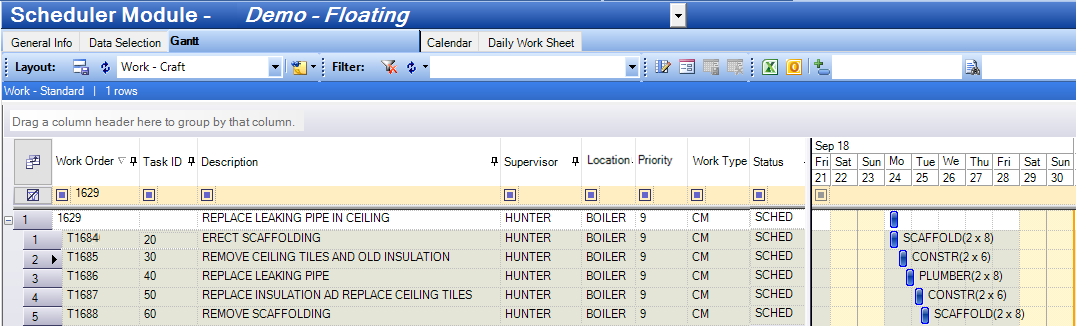

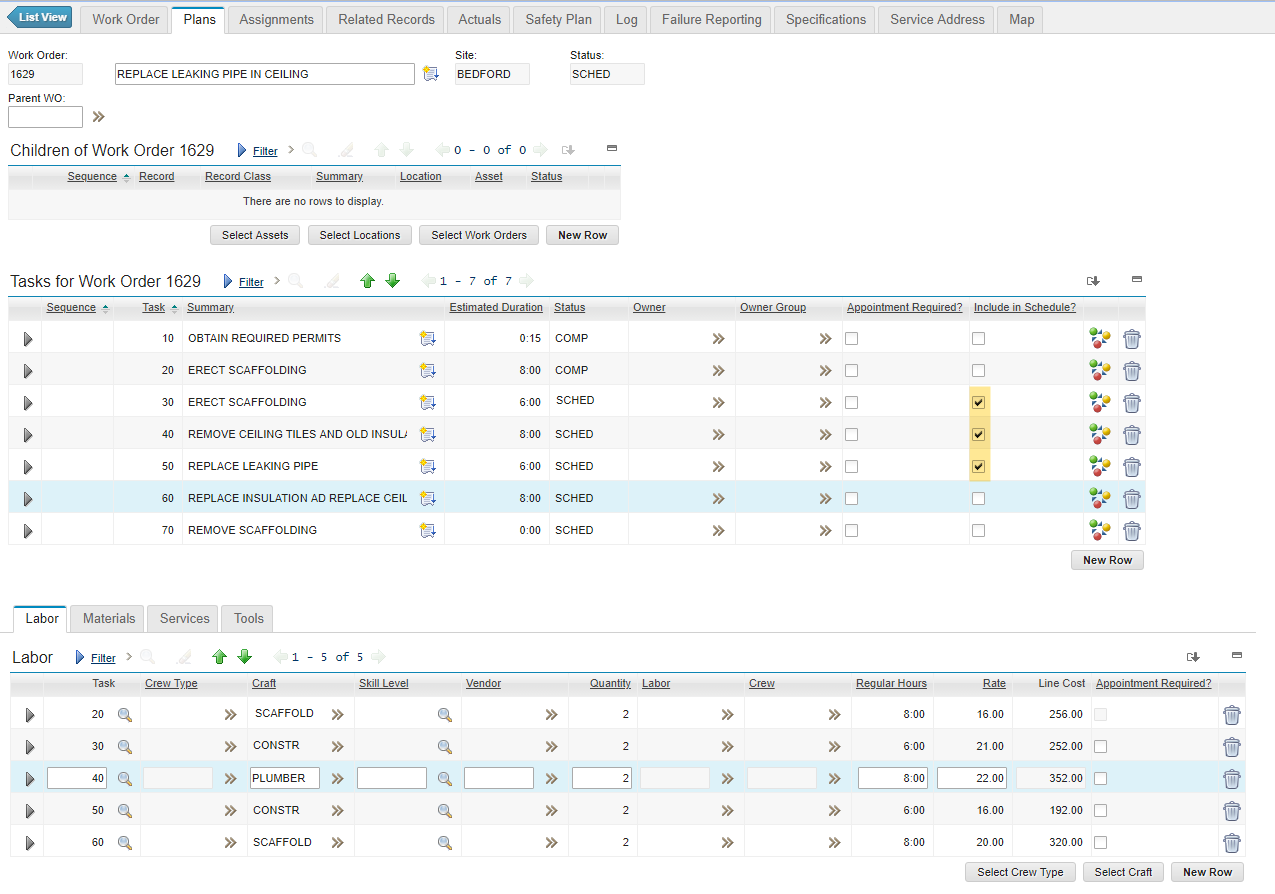

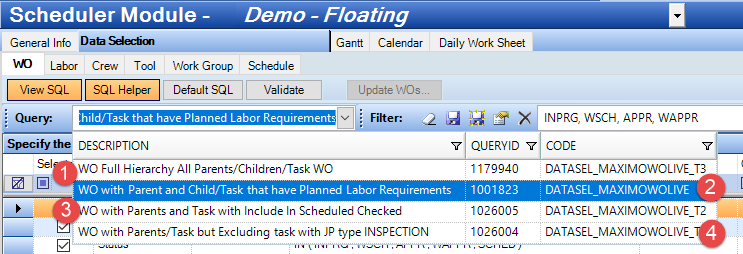

In the screenshots above, the segregation of work has been split out into individual tasks with craft requirements on tasks 20-60.

The challenge of scheduling only on the parent is that it becomes difficult to:

- Understand the progress of each of the individual tasks: Using the example above, how can you know which tasks are complete, in progress, or not yet started if you only have one parent WO for all of those jobs?

- Know who is responsible: When work is scheduled only on the parent, you won’t see which crews or technicians are accountable for the different tasks. The technician from the SCAFFOLD craft is responsible for the scaffolding and is different than the person from the PLUMBER craft who is responsible for the pipe replacement.

- Change the status to accurately reflect that task: Just like you can’t see the progress of individual tasks, you also have no way to record it. There’s only one parent WO, so it’s a one-status-fits-all situation, even though “Erect Scaffolding” might be complete, and “Remove insulation” may be in progress, it’s all going to have the same status.

- Set predecessors and successors: There’s a specific order in which this work needs to be carried out. Obviously, the pipes can’t be replaced prior to removing the ceiling tiles, and those can’t be removed without first erecting the scaffolding. Scheduling on the parent, you can’t schedule when these individual tasks should take place or in what order. You need to have individual WO rows as tasks or as children to accomplish that.

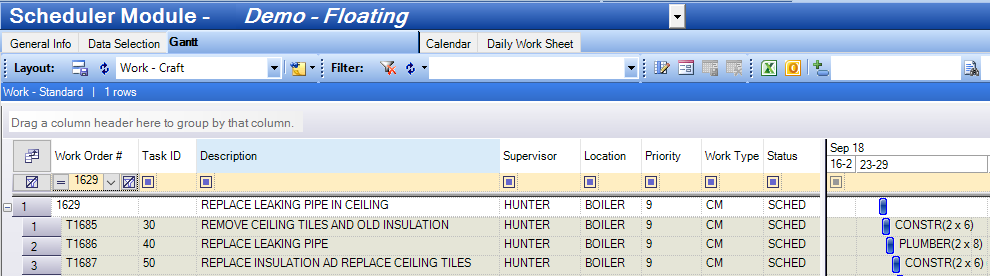

In the screenshot above, we’re only bringing in WOs that have craft requirements. As you can see, Tasks 10 and 70 were not brought into the schedule because they do not have craft requirements associated to them. This is one of the many different data selection query templates that can be utilities from Prometheus Routine Maintenance.

How to Effectively Schedule on Child or Task WOs

So, that sounds like we should all switch to scheduling at the child Work Order level, doesn’t it? Not so fast. There are plenty of situations where that isn’t practical or necessary.

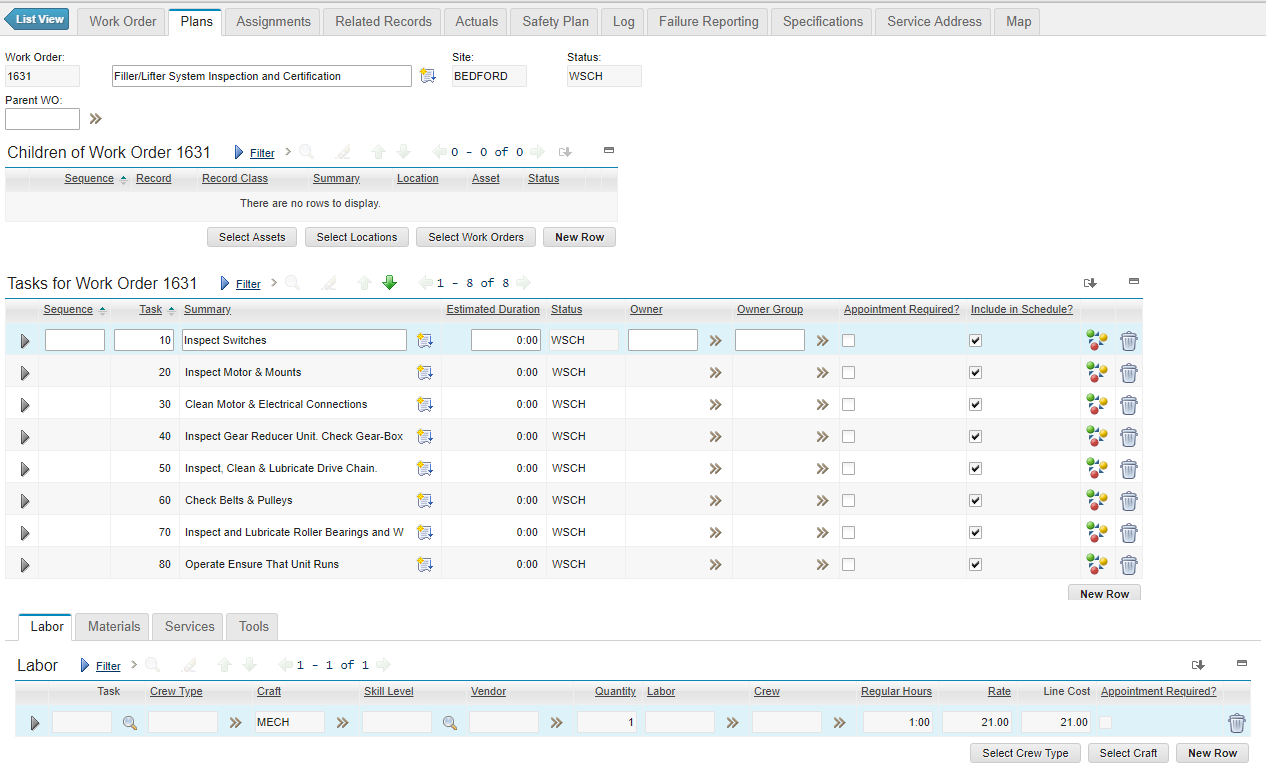

Consider a more traditional PM – say, a "Filter/Lifter System Inspection and Certification". There might be eight steps in that inspection, but it might be possible for a technician to complete the entire inspection in under an hour. There aren’t multiple crafts. The individual elements of the inspection are really checklist items for the technician and because they will all be taking place in quick succession, they do not need to be scheduled individually.

So, for our client, it wasn’t as simple as bringing in all the parent, child, and task WOs and creating a schedule. When they did this, bringing in all these “checklist type” WOs resulted in their data skyrocketing from approximately 800 WOs to 6,000. This added a ton of “noise” that the Planners and Schedulers didn’t need to see. Clearly, that wasn’t going to work.

In talking with their team, we determined that their Planners and Schedulers only needed to see the WOs with craft requirements, since those WOs without craft requirements did not need to be scheduled individually. Then, we built them a schedule view that conditionally loaded only the WOs with craft requirements associated to them.

This narrowed down their data considerably, so that they could schedule only the child/task WOs that needed to be scheduled, without having to sort through piles of data they didn’t need.

The screenshot above shows the "Filter/Lifter System Inspection and Certification" WO in Maximo and its associated tasks.

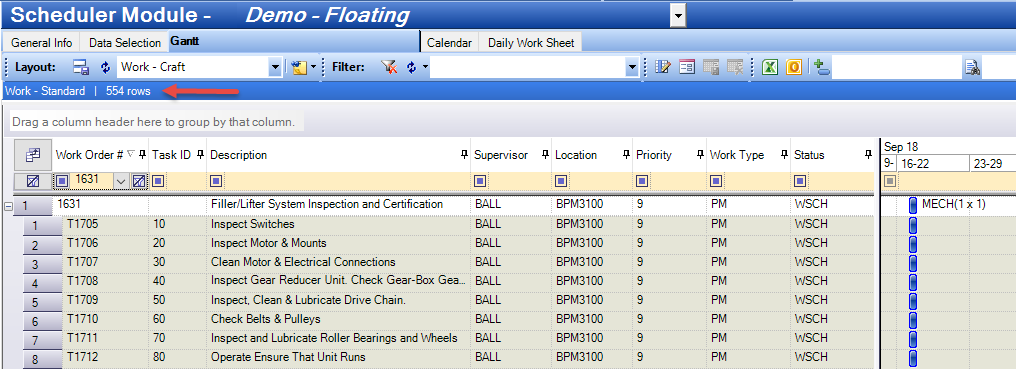

In the screenshot above, you can see that 554 records are brought into the schedule because it is loading all tasks, regardless of the type of WO.

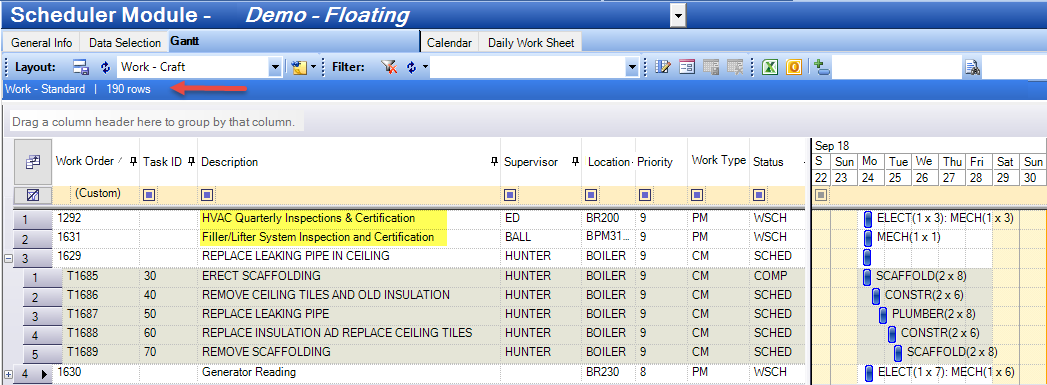

The row count decreases tremendously by excluding task WOs from the schedule where the job plan type is "Inspection". That's 34% (or 364) fewer WOs being loaded into your schedule each time you open, publish, or refresh, which increases your productivity and efficiency.

A Different Method to Conditionally Bring in Tasks

But of course, not every organization is the same. Depending on your team, your processes, and your needs, conditionally loading only the WOs with craft requirements in this way may not work for you. But that doesn’t mean all hope is lost.

Another client we work with uses IBM Maximo’s “include task in schedule” checkbox to determine which child/task WOs should be loaded into their schedule. This method achieves something similar to the custom conditions we were able to configure for the other client but allows the schedulers to cherry pick the individual child/task WOs that need to be included in the schedule. Note: This can also be set accordingly on the job plan, which will carry over to the WOs.

It’s also important to note that Prometheus Routine Maintenance could allow one schedule to use the “include task in schedule” checkbox method, while other schedules could return all task WOs (or other schedules could use a different methodology) when loading similar data. This view does not have to be universal across your Planning and Scheduling team.

The screenshot above shows the "Include in Schedule" checkbox in Maximo.

As you can see, this schedule in Prometheus includes only those tasks that have the "Include in Schedule" checkbox checked.

Setting up Conditional Loading in Your Planning and Scheduling Tool Should Be a Breeze

Depending on your processes and data, conditional loading can have outstanding benefits for your organization. We’re talking about “hiding” hundreds – if not thousands – of Work Orders from view so that your Planners and Schedulers don’t see the WOs that do not require scheduling actions. Not to mention that you’ll have an easier time scheduling to the child or task level when it’s appropriate – and gain all the advantages of scheduling in that manner.

The real magic is that with Prometheus Routine Maintenance's schedule template queries, it’s simply a matter of selecting the type of template you’d like to use. These schedule templates can be used to meet other requirements too. You can configure the conditions of what your schedule does and doesn’t load to meet your needs – and spare yourself sifting through mountains of data.

These are just a few examples of the query templates that can be utilized. Based on your own requirements, additional template types can be created easily.