It’s a tale as old as time: Maintenance points the finger at Operations, and Operations hits back with complaints about Maintenance. These two departments often rely heavily on each other, supporting one another’s success. And yet a common complaint amongst companies in oil and gas, nuclear, facilities management, chemicals, power gen, utilities and more is that it is difficult to get these two to work together effectively.

How can we harmonize the permitting process between Maintenance and Operations? Try these three tips.

Tip #1: Enforce the Permitting Process… for Everyone

Manual Permit to Work (PTW) processes, by their very nature, allow personnel to perform the permit preparation, issue and surrender activities with a high degree of flexibility. And while flexibility sounds great, it can be the leading cause of miscommunication and frustration between employees – regardless of which department they’re in.

Too much flexibility allows for steps to be overlooked or skipped, and that increases the risk of incidents occurring.

All Permit to Work processes require certain activities to be completed in a pre-determined safe sequence before moving on to the next step. But how can a paper permit system enforce the process? The employee can simply skip that section or skip the permit altogether. What’s to stop them?

Your processes are in place to keep employees safe; it’s likely your organization also designed them to keep you compliant with federal and local occupational health and safety regulations. No wonder, then, that Operations will raise the red flag when these processes are ignored or “tweaked”.

One of the best ways to foster strong working relationships between Maintenance and Operations is to ensure that everyone adheres to the permit process.

How Can You Make It Happen?

Generally, a digital Safe System of Work will enforce the sequence of events. This can alleviate some of the personnel overhead that would otherwise be incurred by pairing a safety or compliance worker with the maintenance crew for the duration of dangerous tasks.

Electronic PTW systems prevent personnel from taking shortcuts or moving outside the approved process. All actions in the permit lifecycle are recorded in an electronic audit trail. This encourages personnel to follow proper, safe procedures – because the digital paper trail is far more auditable than a manual process – meaning everyone can be held accountable.

Tip #2: Open up the Lines of Communication

Many issues between Maintenance and Operations stem from a lack of visibility and communication. It’s not that one doesn’t want to work with the other – it’s that keeping all the pertinent personnel in the loop is a nightmare.

This lack of visibility is not only frustrating, but it can cost the organization in time, resources and thousands of dollars of lost production. For example, there can be significant delay in returning a plant to service after a scheduled shutdown/outage, because of the large numbers of permits which must be surrendered and restored prior to plant restart.

It’s often tough for employees to see the status of permits, particularly those with shared isolations. This means additional checks to ensure breaches do not occur. A lot of effort can be wasted simply finding out what state the plant is in and who holds which permits.

What you need is a visual, readable system where you can control user’s permissions and where they can be notified in real-time of the data changes that are relevant to them.

How Can You Make It Happen?

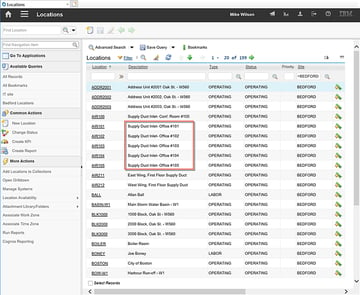

Integrated digital PTW systems deliver huge efficiencies because staff aren’t hunting down information. Connected to your CMMS (such as SAP or IBM Maximo), everyone with permissions can see real-time updates, from changes in permit status to scheduled jobs, permit coverage, status updates and potential conflicts.

Tip #3: Give Your Team a Shortcut…Without Cutting Corners

Let’s get one thing straight: when we talk about making permitting and isolations faster and more efficient, we aren’t talking about cutting corners, skipping steps, or doing anything that would jeopardize the integrity of the systems and processes that have been established to keep workers safe.

Efficiency doesn’t equal low quality.

Time-consuming paper processes tie up valuable labor and can lead to human error (think: messy handwriting, incomplete paper permits, stained, lost, crumpled permits.) So, you’re looking for a way to reduce the amount of paper used in your permitting processes, to increase permit completeness and accuracy, and to make the entire process more streamlined. While few organizations are ready to go 100% paperless, simply replacing some or most paper elements with digital ones can drastically improve your processes.

How Can You Make It Happen?

Electronic systems generate all or most permit documentation, including tags, quickly and efficiently. Vital information is entered once – in the Work Request or Permit Application – and then automatically transferred, as required, to isolation and restoration checklists, permits, certificates and tags. Not only is this significantly faster, it also substantially reduces the risk of errors.

Even more importantly, choosing a digital solution that can work on Mobile is vital. A mobile permitting solution enables employees to enter data from the field, whether they are online or not. It is the fastest and most accurate way to capture their data, causing the least interruptions to their wrench time.

Bonus Tip: Make Training and User Adoption a Breeze

How easy is it to onboard new personnel right now? How long does it take them to understand the intricacies of your paper system? And how long does it take before they start cutting corners, deviating from the process, and adopting other “bad habits” from their colleagues?

Get everyone aligned and on-board with a solution that is easy to use, integrates seamlessly with your CMMS, and guides the user through a visual experience that prevents missing crucial steps.

How Can You Make It Happen?

You guessed it. Pick the right digital Integrated Safe System of Work. With an ISSoW that is designed with the end user in mind, training is easy – because the application is much like the common tools they already use in their day-to-day lives.

Maintenance, Operations and Permitting: Digital Is the Bridge That Connects Them

At the end of the day, Maintenance and Operations want to get along. And they can, if they have consistency, communication, visibility and accountability. No one can be exempt from the quality processes that you have put in place to keep your maintenance technicians safe. But equally, no one wants to waste valuable time on tedious, repetitive tasks that could be handled more efficiently.

The key is to provide these two departments with a thoughtfully designed, scalable system that has powerful capabilities, strict permissions controls, a simplified visual layout, and an optional mobile application for even more control.

Are you searching for a permitting and safety system that brings Maintenance and Operations together? Prometheus ISSOW (Integrated Safety System of Work) can help. Contact us today to learn more.