Imagine this: you’re called into work a half hour earlier than usual for a big meeting. Since there’s no time to make coffee at home, you know you also have to skip your favorite breakfast sandwich on the way. But that’s okay; somebody said there would be donuts at the meeting. You get to work with a dozen other bleary-eyed coworkers, who are all a little prickly without their morning java too.

The meeting starts… sort of. The presenter has no handouts and there is a technological malfunction so the PowerPoint is not working. In short, the important meeting everyone schlepped themselves to so early in the morning is a total disaster.

And there are no donuts.

Failing To Plan Is...

In the maintenance arena, poor planning—or a total disregard for planning—equates to haphazard conditions, or even dangerous, costly ones. Without an effective plan, maintenance efforts can result in unsafe operations, poor asset quality and higher levels of operational downtime. Time management guru Alan Laiken summed this situation up perfectly when he said,

“Failing to plan is planning to fail.”

What exactly happens when there is ineffective planning? Maintenance is reactive rather than proactive, delays are the norm, performance is poor, everyone always seems too busy to make improvements, and supervision is inefficient and ineffective. Not only is there generally poor communication, but there are often stressful confrontations with operations due to asset unavailability.

These are worst-case scenarios that could be dramatically reduced with better maintenance planning. But how do you improve conditions that support good planning?

- Promote thorough preventative maintenance inspections and failure analysis

- Create an effective Predictive Maintenance Program and encourage a complete equipment work history

- Finally, encourage timely reporting by operations and call for an overall planning program

Organizational-wide Benefits of Proper Planning

The advantages of proper planning are apparent. With an efficient maintenance plan in place, all departments and impacted personnel are affected.

For the Maintenance Technician:

- Required tools and materials are available at the job’s outset

- Nobody has to guess what tools to use, and the technician has the right tool for the right job

- There is more hands-on time because the technician isn’t searching for parts and tools

- Step-by-step maintenance procedures are available

- There is a good indication of how long the job should take

For the Maintenance Supervisor:

- There is an overall plan for daily work

- For each job planned, there is advanced knowledge of manpower and required time

- There is a centrally located information source

- They can pay closer attention to supervisory duties

- Job goals are clearly outlined

- Clerical work is reduced

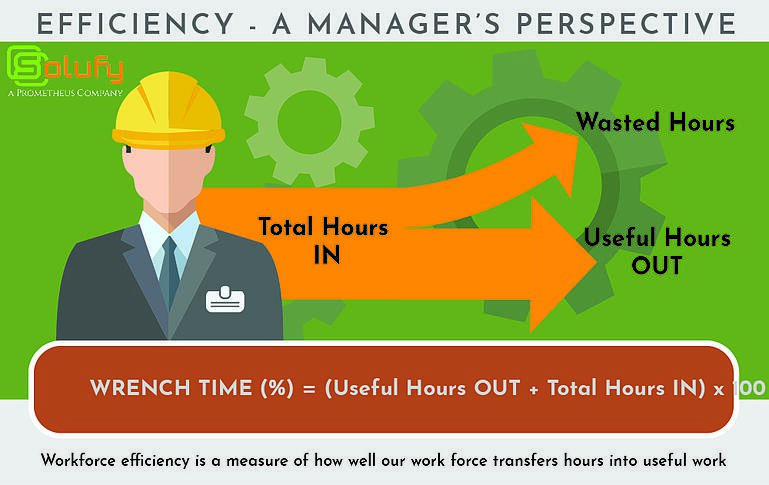

For Management:

- There is a reduced overall maintenance cost

- Labor needs are accurately forecasted

- There is better awareness of peak workload levels

- Each employee works more productively

- There is a better performance and corrective action evaluation

- Unnecessary or questionable work requests are easier to see

- Overall effectiveness is better measured

- There is better, more effective communication between operations and maintenance

- Maintenance and asset performance reporting improves

Integrated Communication Is Vital to Proper Planning

Communication between the planner and maintenance manager is critical. Not only should there be regularly scheduled meetings to critique completed schedules and finalize the upcoming schedule, but they should also be flexible enough to communicate when necessary.

When critiquing a schedule, first ask if the schedule was completed successfully. If not, it is useful to know:

- Did poor planning impact this?

- What problems existed?

- What issues could have been avoided?

- What can be done differently in the future?

Supervisors should also critique technicians, while technicians and supervisors should be encouraged to provide ongoing feedback to the planner outside of meeting times.

Mutually Exclusive Roles in a Maintenance Department

It’s apparent that each role is critical but exclusive to the necessary position. Maintenance management runs most efficiently when each worker is provided with a well-defined task that should be completed in a specific time and manner.

A technician carries out the specific hands-on work while a supervisor focuses on job instructions, quality, safety and work efficiencies. Each has a specific aptitude for their job but are not effective in planning. However, a qualified planner provides the skills to create careful, well-prepared plans and schedules.

A planner is an analytical, sequential thinker who pays close attention to detail.

It’s important that a planner does not have overlapping job responsibilities. In a smaller organization, the planner may also be the scheduler and material coordinator but in a larger company, the planner solely works on this component.

A well-trained planner efficiently coordinates manpower loading, priority jobs and reporting to management. The planner also streamlines the planning process and ensures that it runs efficiently.

In every successful organization, roles are clearly defined, constructive communication is emphasized and processes are laid out and followed. When this happens, maintenance and planning can more effectively shift from a reactive state to a proactive one.

Finally, you may be thinking, “There is a lot ahead of me to improve my planning and scheduling functions.” You might be afraid that there is simply not enough time to take on this task which is a sign that improvement is needed. The answer is to start small, maybe focus on the assets that cause the most problems, or focus on critical assets. Don't worry about a perfect plan at first; you need to start somewhere and continuously improve what you are doing.

Plan, Do, Check, Act.

And remember what Edwards Deming said:

“It is not enough to do your best; you must know what to do, and then do your best.”