Standard maintenance procedures (SMPs) vary highly in quality and thoroughness, even within one organization. The most basic view of SMPs is that they are simply lists of the steps required to properly carry out a maintenance task. That definition leaves a lot of room, as it includes the most complete and detailed SMPs as well as ones that list generic, broad tasks like “Overhaul engine.”

This lack of consistency and quality can hurt asset-intensive companies in spaces such as oil and gas, utilities and power generation, petrochemicals, pharmaceuticals, mining and metals, aerospace and defense, and others. Data shows that creating and optimizing SMPs benefits planning and scheduling and improves maintenance outcomes.

The Impact of Poor Standard Maintenance Procedures

SMPs share a similarity with maintenance planning and scheduling in that you are always better off with something than you are with nothing. Any written SMP—no matter how poorly constructed—can serve as a helpful guide if certain conditions are met. The most common prerequisites of these SMPs are that the technician knows the equipment and has performed this job before.

This is better than nothing at all, but there is certainly room for improvement! If you want to realize the potential benefits of standardizing your procedures, you must construct your SMPs in such a way that any qualified technician can accomplish the task, not only one who is familiar with your particular equipment or processes.

In addition, SMPs should be written to provide the single best way to perform those tasks. There are almost always multiple paths to an objective, but there is always one path that is the most efficient. Your SMPs should reflect that most efficient path to the goal.

The most effective SMPs allow organizations to continue to have the right maintenance work done in the right way no matter what — whether a long-term employee is doing the job for the 100th time or a qualified but newer technician (or even a contractor) is taking the reins for the first time.

Management of Change for SMPs

Any work on your standard procedures should be done with a formal Management of Change (MoC) process. This helps ensure that any changes made to the SMPs will move them closer to the goal of finding the most efficient path to the desired outcome. Making use of a formal MoC process ensures that your SMPs stay on track, and everyone is informed of the changes.

Your organization may already have a formal MoC process in place. If so, it's essential that you use that process for any changes to the SMPs to ensure that everyone impacted by the proposed change is made aware of it, and the changes move through the approval process in the right way.

You may also have a legal obligation to use the existing MoC process. Some jurisdictions have regulations regarding the use of MoC in industrial settings. Departing from your organization's existing process may not just get you into trouble with your company, but regulatory bodies and the government as well.

In addition, not following the existing MoC process can lead to important updates not reaching everyone, possibly leading to a safety incident or worker injury.

Benefitting from Standard Maintenance Procedures

The benefits of SMPs are incremental and wide-ranging. Here are just a few of the benefits made possible with improved SMPs:

- Simplified and more efficient job planning

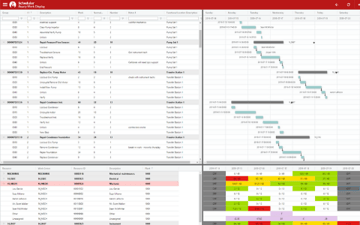

- Easier and more flexible maintenance scheduling and resource allocation

- Better documentation of discoveries and improved sharing of knowledge

- Improved asset and maintenance data collection

Increasing Planning and Scheduling Accuracy

Maintenance job planning defines what needs to be done, why it needs to be done, and how those tasks should be completed. Planning requires in-depth technical knowledge, but even the most experienced planner can benefit from thorough SMPs.

Well-designed SMPs will list not just the steps needed to accomplish a maintenance task, but the required tools and materials as well. Planners experience a huge boost in efficiency if everything is laid out for them. Situations may come up that are not covered by existing SMPs, but even in this case it may be possible for planners to modify a procedure that’s already documented.

Maintenance scheduling defines when maintenance tasks are done and who does the work. Schedulers will also be more efficient if you’ve built SMPs with a deep-rooted attention to detail. To illustrate why, let’s imagine two different facilities producing identical widgets.

Facility A has SMPs, but they’re vague and don’t completely cover all the critical assets. Technicians use their individual knowledge to perform maintenance tasks. The SMPs in place are treated as aids to their memory, but nothing more.

It’s a different story at Facility B. Here, every routine maintenance task is thoroughly documented and detailed. In fact, most of the SMPs are even accompanied by photos showing lubrication points, isolation points, required parts, etc.

The schedulers at Facility B produce much more efficient schedules than their counterparts at Facility A, and they do it in less time. Facility A’s schedulers must often build their schedules around the knowledge and capabilities of the individual technicians.

Sometimes this means they delay jobs just to make sure the right technician is doing the work. Maintenance scheduling is difficult enough under the best of circumstances. Introducing complications like this make it even more challenging.

At Facility B, though, the schedulers don’t have this concern. If they have an electrical job, they can simply schedule the first available qualified electrician. Both they and the electrician know that the SMPs will contain all the information needed to complete the assigned task successfully and safely.

Sharing Knowledge Faster and More Thoroughly

Technicians often discover new knowledge about an asset when working on it. Properly prepared and documented SMPs help to ensure this knowledge isn’t lost by making it accessible to everyone who needs it. Your SMPs should always be subject to feedback and revision. Assets aren’t static. They change over time, and your SMPs must change with them.

Thorough SMPs also ensure that all technicians are made aware of updates and changes to long-standing procedures. Having them documented and referenced in the SMPs means they’re less likely to be forgotten than if you simply tell them verbally or send around an email. In addition, the information will even reach technicians who were out sick or on vacation if you make sure to include it in the SMPs.

This also makes training of new hires faster and more efficient. New craftspeople can quickly get up to speed on the individual quirks of your assets just by reading the SMPs when they’re called on to work on them.

We often hear the term “tribal knowledge” used to describe information known inside a group, but largely unknown outside of it. One of the benefits of SMPs is that they can be used to verify tribal knowledge, and then make it accessible, up-to-date, and useful to everyone in your organization.

Gathering More Complete Data with Standard Procedures

SMPs can provide you with considerable information on an asset’s history, particularly:

- What maintenance work has been done on the asset

- Why it was done on the asset

- When and how often the asset has undergone maintenance work

This data can help you to make adjustments to job plans and how often certain routine tasks are performed. Very often, you can even use the collected data to help with root cause analysis of failures.

Of course, you can only really rely on this information if you have reason to believe the procedures have been followed. Your culture must support the use of SMPs at all levels for them to be an effective information gathering tool. It may be necessary to change your company culture to gain this benefit.

A mobility solution designed for maintenance can aid in this culture change. A solution like Prometheus Mobility can be configured to ensure SMPs are thoroughly followed, and any changes documented. The solution presents the task steps in order and will not let the user proceed until each step has been completed.

You’ll realize another benefit from empowering your workforce with a mobile solution: the data gathered will be much more accurate and less subject to human error. Even if technicians are dutifully following every single step in your SMPs and documenting it every step of the way, sooner or later they will make an error.

A good mobile solution that’s designed for the needs of maintenance helps to reduce data errors by removing the manual part of the data entry process and the time delays between doing the work and entering the data. This allows technicians to concentrate on producing quality work by making data entry guided and immediate.

Creating the Best Standard Maintenance Procedures

The ideal situation is to have a perfectly detailed SMP for every single maintenance task in your entire facility, regardless of how unimportant it may seem or how infrequently it’s performed. That’s a goal to strive towards, but don’t be disappointed if your facility never seems to quite get there. It’s more important to ensure you have the best possible SMPs for:

1) The most commonly performed tasks in your facility

2) The most complicated tasks

It’s possible for these two areas to overlap, but it’s rare. Your buckets will likely remain distinct. The design of both types of SMPs have similarities, but they also differ in a number of important respects.

Your SMPs for the first type will save time on a daily basis and will no doubt help prevent failures. The second type of SMP will also save you some time, but the key reasons for this type of SMP are usually related to worker safety, lessened impact on production, and decreasing failures.

The first stage in designing SMPs for your most performed tasks is to figure out exactly what they are. You probably already have an idea about this, but make sure to confirm it with data from the planning and scheduling staff.

Your efforts will bear fruit more quickly if you start with the most common task and work your way down the list. Your SMPs for these routine tasks should list the following:

- Safety information, including environmental hazards, and any protective equipment required

- Skills and/or certifications needed to complete the task

- Expected length of job duration

- When the job is required and how that’s determined (time, cycles, sensor readings)

- All materials, tools, and parts required

- Any maintenance, tolerances, or standards that must be followed

- A (painstakingly) thorough list of all the steps needed to complete the job

Regarding that last point, it’s not possible to be too detailed here. Never assume that the person doing the work will have the same knowledge you do. The example of too little detail we gave earlier was “overhaul engine.” That’s extreme, but it’s not uncommon to see an instruction like “provide lubrication at lubrication points” without more details.

How many lubrication points are there? What type of lubricant should be used? These questions have obvious answers…if you already know the answers! A technician who is new to the facility or even to that particular asset may not know them. Having the answer right in front of them in the SMPs is the best way to ensure that the job is done right.

You can improve your standard maintenance procedures by including photographs of every part needed and every stage of each procedure. These days, when practically everyone has a camera in their back pocket, there’s really no excuse to not include photos.

Designing the SMPs for your larger, more complicated jobs follows a similar philosophy. The key is to list all the skills, materials, and steps needed to perform the job. The difference in an SMP for an oil change and one for the complete rebuilding of a pump is a matter of degree.

The more complicated and important the job, the more thoroughly documented the procedures must be. Again, step-by-step photos and easy ways for technicians to access critical information in the field are tremendously helpful.

Like our list of key characteristics of standard maintenance procedures above? Download our free Standard Maintenance Procedures Checklist.

Improving Maintenance Outcomes, Large, Small, and In-Between

Your SMPs can enhance your planning and scheduling efforts when they’re properly designed, all technicians have been trained on them, and the culture of your organization supports their use.

Remember, the goal is not to produce documentation. The real goal is improving your maintenance outcomes. SMPs show their worth very quickly by allowing you to access higher efficiencies in your most common tasks.

This alone makes the effort of designing them and training your technicians worthwhile. The fact that you can also use them to ensure larger, more complicated jobs proceed smoothly might be an even greater benefit, but the benefits from the routine tasks will be quicker to make themselves known.

Technicians using SMPs will almost certainly complete tasks faster. This will naturally lead to an overall increase in wrench time for your organization, as technicians can move to the next task faster. However, the increase in speed is not the greatest benefit. Speed, while commendable, is not a benefit if it leads to sloppy work. Perhaps the greatest advantage of SMPs is that they permit technicians to go faster without sacrificing quality.

In fact, the quality of maintenance typically rises as more SMPs are put in place, as long as the procedures are thorough, detailed, and correct. To realize this benefit, you must ensure that the SMPs are actually useful. This means consulting with technicians who know the assets, reading over manufacturer’s specs, and being willing to update the SMPs when you receive feedback from the field.

SMPs that have been crafted with diligence and attention to detail are only part of the solution. For SMPs to achieve their true potential, they have to be used. Planners must consult them when drawing up new job plans, and update them as feedback comes in or new situations arise. Technicians must access them and follow the procedures when performing the work, as well as providing feedback when they’re not working as well as they could.

Just like how any SMPs are better than none, SMPs that are consulted occasionally are better than procedures that are never examined. However, you will only get the most benefit from SMPs if the culture of your organization supports their use.

Overcoming the Biggest Barrier: Your Culture

It would be nice to believe that technicians, planners, and schedulers will see the benefits of SMPs and rush to adopt them when given the chance. This isn’t very likely. People get used to doing things a certain way. They’ll resist when the old ways are replaced. Very often this resistance comes up even when the new method is obviously superior.

No matter the organization, culture comes from the top. A large-scale SMP project will need an executive sponsor who truly believes in it and sees the value of adopting standardized procedures. However, simply rolling out the change from above will probably increase resistance from the staff working in the field or on the floor.

Your best bet to change your culture in favor of SMPs is to involve people at all levels. In fact, this is a case where you might want to start at the bottom. You are more likely to secure an executive sponsorship for your SMP-improvement project if you have the backing of many people in the maintenance department, including technicians, planners, schedulers, and supervisors.

This will help, but it’s not enough. Executives want numbers. The more figures you can provide that show how SMPs will improve outcomes and lower costs, the higher your chances of success.

This seems to present us with something of a Catch-22. You can’t change the culture to adopt SMPs until you have an executive sponsor, and you can’t get an executive sponsor until you have proof that the SMPs will work.

The solution is to start small, without an executive sponsor. Think of your ultimate goal as something like summiting Everest. Mountaineers don’t march straight to the peak. It’s much too high to make it in a single journey. Instead, they make a series of base camps, and use those as launching points to climb progressively higher.

You can start benefitting from SMPs in the same way. Start by getting buy-in from a few critical people in the maintenance department and design (or re-design) SMPs for just a few of the most critical assets. Over time, the benefits of the new SMPs will become clear in the form of lowered maintenance costs and/or fewer failures.

Now you have data that can be used to convince others in the maintenance department and show executives the return on investment.

Use Standard Maintenance Procedures to Improve Maintenance

Your organization probably has at least a few SMPs in the vaults, and it’s important to remember that poorly designed SMPs are still better than nothing at all. However, the greatest benefits will only be realized when the procedures are accurate, thorough, and extremely detailed.

When you're writing an SMP, your goal should always be to create a guide so complete that any qualified technician can follow it and complete the work adequately. The "qualified" part is important. You wouldn't hand electrical work to a mechanic, or vice versa.

The technician's experience, however, shouldn't be a factor. Whether they're brand new to the facility or practically a permanent fixture, SMPs should give them all the information required to get the right work done, on the right asset, at the right time.

There is such a thing as a perfect SMP, but only at a certain time. The business and its operating environment may change drastically, and SMPs must change to reflect that. Every SMP should be subject to periodic review and refinement.

It's also vital to take into account the feedback received from other stakeholders, especially planners and technicians. If they tell you something is wrong with one of the standard procedures, you need to listen. That doesn't always mean that you need to take their advice, but you do have to be open to it.

By creating and optimizing SMPs that follow best practice, you're putting the maintenance department and the company as a whole on the road to a more productive future.

Learn more about how Prometheus Group can help your organization with maintenance planning and scheduling management today.